Keeping the oil reservoir of your Fellowes C-420C shredder full is crucial for optimal performance, especially if the shredder sees regular use in high-volume environments. This model has an auto-oiling system, which ensures that the blades are lubricated for smooth operation and reduced wear. If you notice reduced efficiency, hear squeaking, or see the low oil indicator light, it’s time to refill the oil reservoir.

This guide will walk you through the importance of regular oiling, how to refill the reservoir properly, and provide tips to maintain the shredder’s long-term functionality.

Why Refilling the Oil Reservoir Is Important

Regular lubrication keeps the shredder blades running smoothly by reducing friction, preventing overheating, and minimizing wear. Here’s why it’s crucial to keep the oil reservoir full:

- Reduces Friction: A well-lubricated shredder operates with less resistance, preserving the motor and blade performance.

- Prevents Overheating: Without proper lubrication, the blades can heat up due to friction, potentially causing malfunctions or shortening the shredder’s lifespan.

- Enhances Efficiency: Oil ensures that the machine shreds efficiently, especially during high-volume tasks. When the blades are properly lubricated, they handle large stacks of paper with ease, helping avoid jams and stalling.

Step-by-Step Guide to Refilling the Fellowes C-420C Shredder Oil Reservoir

Maintaining the oil level in the Fellowes C-420C shredder’s reservoir is essential for ensuring smooth operation and prolonging the life of the blades. The following steps will guide you through refilling the oil reservoir safely and effectively.

Step 1: Gather Supplies

- Required Oil Type: Only use Fellowes-approved non-aerosol, vegetable-based shredder oil. This specific oil type is recommended because it’s designed for shredders, ensuring compatibility with the auto-oiling system and preventing potential damage to the internal components.

- Soft Cloth or Towel: Have a cloth ready to catch any accidental drips or spills around the reservoir opening.

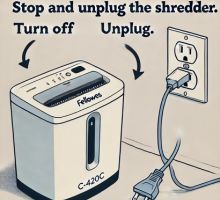

Step 2: Turn Off and Unplug the Shredder

- Safety First: Before you begin, always turn off and unplug the shredder. This precaution prevents accidental activation and ensures safety while handling the machine.

- Double-Check Power Off: Confirm that all indicator lights are off, showing the shredder is completely powered down.

Step 3: Locate the Oil Reservoir Cap

- Find the Cap Position: The oil reservoir cap is generally found on the top or side of the shredder. Look for a small, secure cap labeled “Oil” or consult your manual if needed.

- Inspect the Cap and Surrounding Area: Ensure there is no dust or debris around the cap that might fall into the reservoir during the refill process.

Step 4: Open the Cap and Begin Refilling

- Unscrew or Lift the Cap Carefully: Remove the oil reservoir cap gently. Place it nearby in a secure location to avoid misplacing it.

- Pour Slowly to Avoid Overfilling: Begin pouring oil slowly and steadily into the reservoir. The Fellowes C-420C’s reservoir typically holds around 12 ounces (355 ml), but always refer to the manual for precise capacity limits.

- Monitor Oil Level: Watch the oil level closely as you pour. Overfilling can cause leakage and may interfere with the automatic oiling function, so it’s crucial not to exceed the reservoir capacity.

Step 5: Distribute the Oil Evenly Across the Blades

- Activate Reverse Mode: After filling, plug the shredder back in and turn it on. Run the shredder in reverse mode for 10-15 seconds. This step helps distribute the oil along the blades and lubricates the entire cutting mechanism.

- Observe for Smooth Operation: Listen for any changes in noise. A well-lubricated shredder should run smoothly and quietly, indicating that the oil has been evenly distributed.

Step 6: Replace the Cap Securely

- Double-Check the Cap Position: After refilling, securely reattach the oil reservoir cap. Ensure it’s firmly in place to prevent spills and to maintain the auto-oiling system’s pressure.

- Wipe Down the Area: Use a soft cloth or towel to clean any oil residue around the cap and reservoir area. This prevents dust from sticking to any oil spills and keeps the shredder clean.

Step 7: Test the Shredder with a Single Sheet of Paper

- Confirm Proper Operation: Insert a single sheet of paper to test if the shredder operates smoothly. This quick test checks whether the oil has been adequately distributed, allowing the blades to cut efficiently and without excess friction.

- Repeat If Needed: If you still hear squeaking or grinding noises, consider running the shredder in reverse again to ensure all blades are thoroughly coated.

By following these steps carefully, you can effectively maintain the oil level in your Fellowes C-420C shredder, ensuring smooth and efficient operation. Regularly refilling the reservoir will keep your shredder performing well, reduce friction on the blades, and prevent potential malfunctions.

Tips for Maintaining the Fellowes C-420C Shredder’s Oil System

Keeping the oil system in top condition is essential for the smooth operation and longevity of your Fellowes C-420C shredder. The auto-oiling feature, when well-maintained, reduces friction, prevents jams, and keeps the shredder running efficiently. Here are some practical tips to help you maintain the shredder’s oil system:

1. Monitor the Low Oil Indicator Regularly

- Importance: The low oil indicator on the control panel lights up when the oil level is low. This is an essential feature for the C-420C model, as it reminds users to refill before the blades start experiencing wear from lack of lubrication(c420c_user_guide).

- Best Practice: Check this indicator weekly, especially in high-usage environments, to ensure the auto-oiling system remains functional. Refilling the reservoir as soon as the indicator lights up will prevent any lapses in lubrication.

2. Use Only Fellowes-Approved Shredder Oil

- Importance: Using the right type of oil is crucial for the performance and safety of the auto-oiling system. Fellowes recommends non-aerosol, vegetable-based oil specifically designed for shredders, as it maintains proper viscosity without clogging or damaging the system.

- Best Practice: Avoid generic or petroleum-based oils, as they can interfere with the auto-oiling mechanism and may void the warranty. Only use Fellowes shredder oil to ensure compatibility and longevity(c420c_user_guide).

3. Refill the Oil Reservoir After Intensive Use

- Importance: In high-volume environments, the shredder may use oil more frequently. The auto-oiling system dispenses oil approximately every 500 sheets or 20 passes, so it’s essential to monitor oil levels closely when the shredder is heavily used(c420c_user_guide).

- Best Practice: Make it a routine to check the oil reservoir at the end of each week, or after particularly intensive shredding sessions. Frequent refills help prevent unexpected disruptions in operation, ensuring that the blades stay properly lubricated.

4. Run the Shredder in Reverse After Refilling

- Importance: Running the shredder in reverse after refilling helps distribute the oil across the blades evenly. This step ensures that all parts of the cutting mechanism receive adequate lubrication, reducing wear on specific areas.

- Best Practice: Run the shredder in reverse mode for 10-15 seconds immediately after refilling the reservoir. This will help disperse the oil evenly along the entire blade set, contributing to smoother and quieter operation(c420c_user_guide).

5. Avoid Overfilling the Reservoir

- Importance: Overfilling the oil reservoir can lead to spills, potential leakage, and inconsistent auto-oiling performance. Maintaining the correct level in the reservoir ensures the shredder receives the proper amount of oil each time it’s needed.

- Best Practice: Pour slowly when refilling and stop as soon as the oil reaches the recommended fill line or capacity. Overfilling can create messes and may compromise the reservoir’s design for gradual oil release(c420c_user_guide).

6. Clean Around the Oil Reservoir Cap Regularly

- Importance: Dust and paper particles often collect around the reservoir cap, which can fall into the reservoir during refills. Keeping the cap area clean prevents foreign particles from contaminating the oil and affecting the auto-oiling system’s functionality.

- Best Practice: Before each refill, use a soft cloth to wipe away any dust or debris around the reservoir cap. This small maintenance step prevents contaminants from entering the reservoir and extends the oil system’s life.

By following these maintenance tips, you’ll help ensure that the Fellowes C-420C shredder’s oil system performs optimally. Regular monitoring, correct oil choice, proper refilling practices, and keeping the area clean are essential for long-lasting, trouble-free shredding performance.

Frequently Asked Questions (FAQs)

What type of oil should I use for my Fellowes C-420C shredder?

Use only non-aerosol, vegetable-based shredder oil like Fellowes Shredder Oil. Avoid using general-purpose oils that could damage the shredder.

How often should I refill the oil reservoir?

It’s recommended to refill the reservoir after every 500 sheets or whenever the low oil indicator light turns on.

Can I overfill the oil reservoir?

Overfilling can cause spills and may disrupt the auto-oiling function. Fill the reservoir slowly and avoid exceeding the recommended capacity.

Why does my shredder make a squeaking noise?

Squeaking noises usually indicate that the blades need lubrication. Refilling the oil reservoir should resolve this issue and restore smooth operation.

Is it okay to refill the shredder oil while it’s still plugged in?

No, always turn off and unplug the shredder before refilling the oil reservoir to prevent accidental operation and ensure safety.

Conclusion

Properly refilling the oil reservoir on your Fellowes C-420C shredder is key to maintaining smooth and efficient operation. By following these steps and adhering to a regular oiling schedule, you can prolong the life of your shredder and ensure optimal performance for years to come.

Regular maintenance, including timely oil refills, not only enhances efficiency but also prevents potential breakdowns, keeping your shredder ready for even the most demanding tasks.